Showing you how to increase turbocharger rotor life

Showing you how to increase turbocharger rotor life?

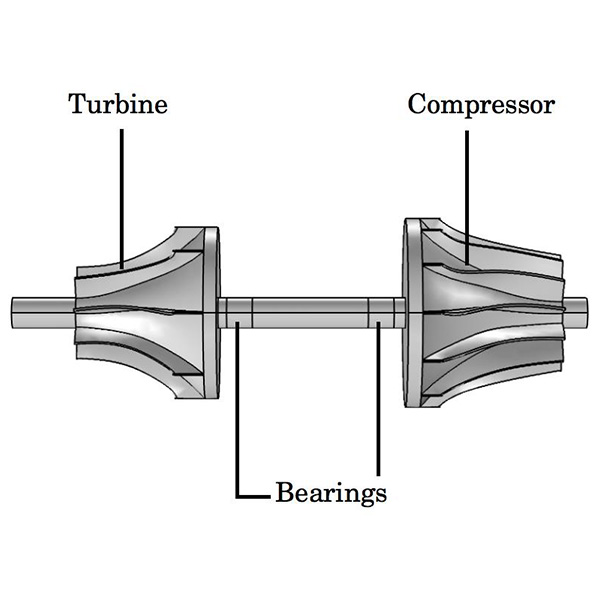

Now most of the small displacement cars will use turbocharger rotor, it can increase the pressure over, unload the excess pressure, thus increasing the life of the throttle body, but the car owner unreasonable operation, will also reduce the life of the turbocharger rotor, in order to reduce the cost of car owners, the following Botao power machinery to teach you how to increase the life of the turbocharger rotor.

1. Do not take the car on the go

After the car engine is started, especially in winter, it should be allowed to run at speed for a period of time to facilitate the high-speed operation of the turbocharger motor rotor before allowing sufficient grease to moisten the rolling bearings. So just after running dry million can not blast the throttle to prevent destruction of the Turbocharger seals.

2.Do not immediately engine off

After the car engine has been running at high speed for a long time, the engine should not be turned off immediately. When the car engine is working, a part of the car oil provides the supercharger stator rolling bearing wetting and used for cooling. Already operating car engine suddenly shut down, oil pressure quickly reduced to zero, turbocharger turbocharged part of the high temperature into the middle, rolling bearing support shell of the heat can not be quickly brought, while at the same time the turbocharger motor rotor is still in the inertial role of high-speed operation, therefore, the car engine hot engine if suddenly shut down, will lead to the turbocharger to stay in the car oil superheat and destroy Sliding bearings and shafts. In particular, avoid the sudden engine shutdown after a few jolts of the accelerator pedal.

3 Maintaining cleanliness

When dismantling and installing the turbocharger rotor, maintain cleanliness, each tee joint must be blocked with a clean cloth to avoid dirt falling into the turbocharger and destroying the motor rotor. Inspection should pay attention to the impact can not destroy the centrifugal impeller, if the centrifugal impeller must be removed and replaced, to solve its dynamic balance test. After the end of the re-assembly, to take down the blockage.

4.To carry out cleaning

Because the turbocharger rotor is often in high temperature operation, its grease pipeline because of the high temperature effect, the internal car oil is very easy to have part of the scale, that will lead to the turbocharger rolling bearing wetting is not enough and destroyed. Therefore, the grease pipeline should be cleaned after a period of operation.

5. Pay attention to maintenance

Before shipment and after receiving the car, the coupling condition of each tube of the gas pipe should be checked to avoid loosening, falling down and leading to invalid turbocharger rotor and gas short circuit fault into the cylinder.