Can I install my own turbocharger parts in my car?

Can I install my own turbocharger parts in my car?

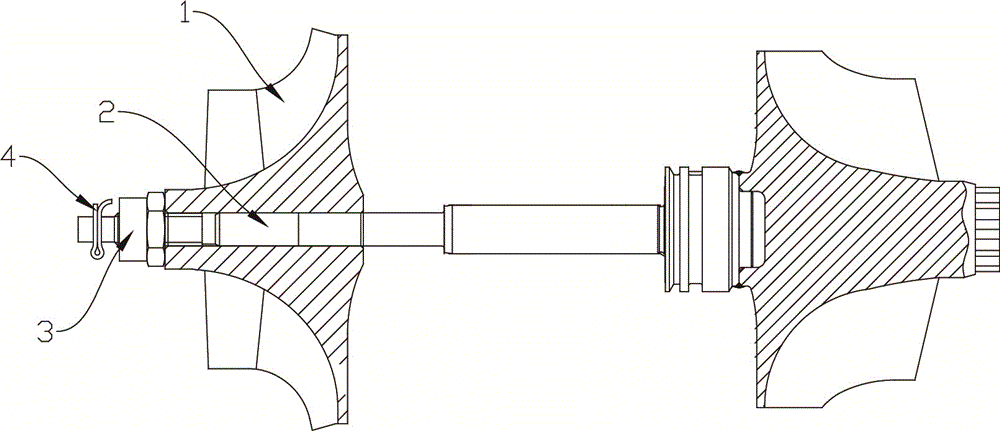

The car turbocharger parts is to use the exhaust gas from the engine to drive the turbine, it is how advanced or a set of mechanical devices, because it often works in a high-speed, high-temperature environment, the temperature of the exhaust gas turbine end of the supercharger in more than 600 degrees, the speed of the supercharger is also very high, so in order to ensure the normal work of the turbocharger, the correct use and maintenance of it is very important.

Car turbocharger parts mainly follow the following methods:

1, After the car engine start, can not rush the accelerator pedal, should first idle for three minutes, which is to make the oil temperature, fluidity can become good, so that the turbocharger is fully lubricated, and then to increase the engine speed, start driving, this is particularly important in the winter, at least need to warm up the car for more than 5 minutes.

2.After a long time running at high speed, the engine cannot be turned off immediately. The reason is that when the engine is working, a part of the oil supply turbocharger rotor bearing lubrication and for cooling, is running the engine suddenly shut down, oil pressure quickly fell to zero, oil lubrication will be interrupted, turbocharger internal heat can not be taken away by the oil, then the turbocharger turbo part of the high temperature will be transmitted to the middle, bearing bearing support shell heat can not be quickly taken away, while the turbocharger rotor still rotating at high speed under the action of inertia.

3, The choice of engine oil must be noted. Due to the role of the turbocharger, so that the quality and volume of air entering the combustion chamber has increased substantially, the engine structure is more compact, more reasonable, higher compression ratio, so that the engine's work intensity is higher. The mechanical processing accuracy is also higher, and the assembly technology requirements are more stringent. All these determine the high temperature, high speed, high power, high torque and low emission working characteristics of the turbocharged engine.

4, Engine oil and filter must be kept clean to prevent impurities from entering, because the turbocharger's rotor shaft and bushings have very little clearance between them, and if the oil lubrication capacity decreases, it will cause premature scrapping of the turbocharger.

5, Need to clean the air filter on time to prevent dust and other impurities from entering the high-speed rotation of the pressure impeller, resulting in unstable speed or increased wear of the bushings and seals.

6, Need to frequently check the turbocharger sealing ring is sealed. Because if the seal ring is not sealed, then the exhaust gas will enter the engine lubrication system through the seal ring, the oil will become dirty, and make the crankcase pressure rise rapidly, in addition to the engine running at low speed when the oil will also be discharged through the seal ring from the exhaust pipe or into the combustion chamber combustion, thus causing excessive consumption of oil to produce "burning oil" situation.

7, Turbocharger to regularly check whether there is a strange noise or unusual vibration, lubricating oil pipe and joint there is no leakage.

8,Turbocharger rotor bearing precision is very high, maintenance and installation of the work environment requirements are very strict, so when the turbocharger failure or damage should be to the designated repair station for repair, rather than to the general repair shop.

9, To keep the air filter clean, compared with ordinary engines, turbocharged engines have higher requirements for cleanliness. This is because if impurities get into the pressure impeller, it can cause unstable speed or increased wear on the bushings and seals.

10, Engine oil to keep clean, turbocharged engines also have higher requirements for engine oil, must be kept clean. In addition, if the oil deteriorates, it should be replaced in time. Otherwise, the oil's lubrication capacity decreases, which will cause insufficient lubrication of the turbocharger bearings and damage, increasing maintenance costs and even causing premature scrapping of turbocharger parts.